Wendy Ward has a new story for worn-out and un-useable waste textiles, that we return them carefully with a letter to the manufacturer, suggesting THEY think about the lack of an end-of-life process.

Once upon a time, an old polycotton sheet reached its end of life. Not absorbent enough to become a rag, unwanted at thrift shops where there’s no demand, no organisation could reuse the materials, it might be repaired a while but most people don’t know how, and shoved in a bin in the UK would mean either incineration or a long journey to be dumped in the Global South.

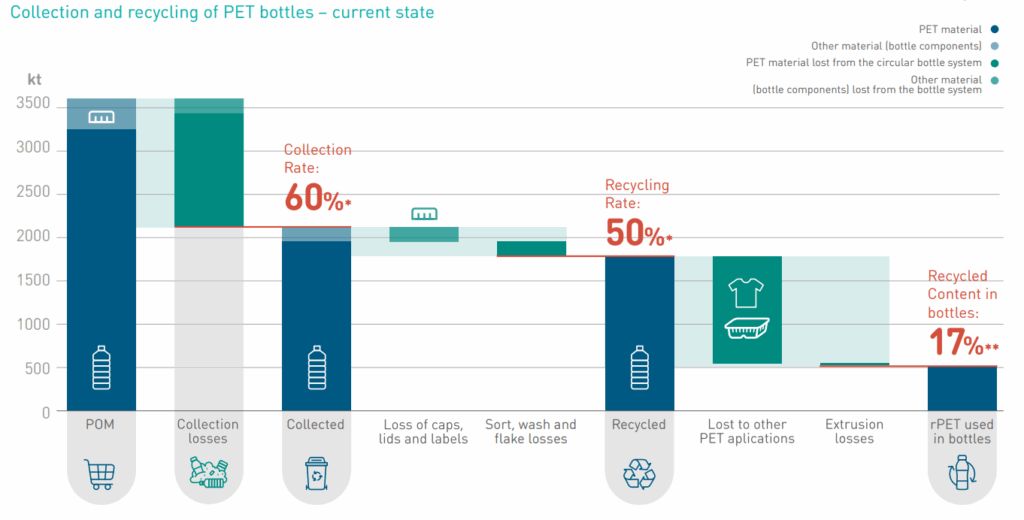

Currently, environmental action charity Wrap claim about 650K tonnes of used textiles are processed out of recycling in the UK, of which 421K tonnes are exported as “waste” colonialism for processing in the global South. While clothing can often be recycled, there is no infrastructure to recycle or repurpose worn bedding and other post-consumer mixed fibre home textile waste.

Enter Wendy Ward, designer, maker, author, and academic, who is holding the creators of the problem accountable. She sent her old sheet back to the retailer with a kindly worded letter asking them to #TakeitBack, and to inform her of what they are doing to address the problem of old unwanted textiles they had produced.

Extended Producer Responsibility (EPR) policies could force manufacturers to take responsibility for the lifecycle of their products, from better design to end-of-use recycling, with fees to support recycling infrastructure, sorting and cleaner incineration. Policies have been implemented in Europe, and could be in the UK. Pressuring responsible organisations to support suitable policy and pay into recycling infrastructure is key, as the government has not yet acted.

Sainbury’s received their 10 year old mixed-source polycotton sheet back from Wendy, with a letter advising them that despite her academic research, she could find no sustainable options like repair, composting, or repurposing, only normal recycling which could see it shipped overseas to be dumped or incinerated.

Her post about her letter went viral, hopefully Sainsbury’s will look into it and take some actions. Wendy reports so far, that she received only a quick customer service response which does not answer the problem.

She recommends more of us get involved, and pressurise these companies to do better.

Take Action

If you would like to participate in the action, and have a mixed-fibre item at end of life, tell them to #TakeItBack.

Launder the items, pack them carefully, and add a polite explanatory letter explaining the recycling issue. Ask what you are supposed to now do with the item, making the problem of unrecyclable consumer textiles visible to those accountable and responsible for its production. Send it recorded mail to manufacturers or retailer.

More details and a template letter here, for people wanting to do the same, many of her Instagram followers are taking this same action. Let Wendy know if you hear anything helpful back!

Resources:

Detailed references for Wendy Ward https://linktr.ee/thatwendyward

@redesign_collective in Instagram coined the helpful term “guerilla EPR” 🙌

More about Wendy Ward’s research here: https://concernedresearchers.org/blog/18-wendy-ward-mom-apr-2025-xdmxm-caghl-xdxh2

We need Extended Producer Responsibility (EPR) policy for textiles (2024) Ellen MacArthur Foundation. Available at: https://www.ellenmacarthurfoundation.org/epr-policy-for-textiles (Accessed: 1 June 2025).

Implementation of EPR in Europe : Saint, M. (2025) ‘Fashion brands face growing EU pressure to cut textiles waste’, Financial Times, 22 May. Available at: https://www.ft.com/content/02d6d242-5a1a-4628-a861-a5e880b52575 (Accessed: 1 June 2025).