That shiny new top for a special night out, or fresh bright cushion cover in the hotel room, or no-iron sheets in the guest room, all have one thing in common – made with polyester, they get old, and ugly, and wear out. And existing recycling has limited options for this – despite being told to put old things in the correct recycling bin, it cannot all be recycled sustainably.

Once too worn out for its original purpose, or to be reused, repaired, refurbished, or repurposed, then basic materials should be recovered from the item. With polyesters, chemical recycling is an option (dependent on the mixture of fibres involved). The process is technically complex, and a lot of waste material escapes.

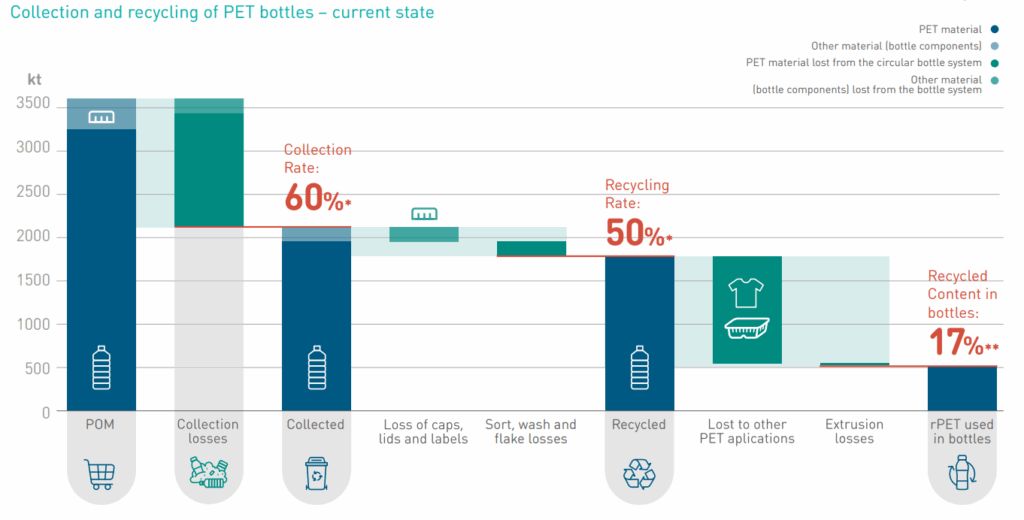

PET (polyethylene terephthalate, one kind of polyester, used for bottles, trays, and fabric) is recycled a lot – about 50% in Europe. About 17% in 2022 of recycled PET material became new bottles, the rest plastic packaging and mixed fibre clothing or was lost during in the recycling process.

So up to 63% of PET is lost each cycle as waste, see graph above (recycled PET packaging/trays and mixed fibre polyester textiles, are not themselves recycled much). Each cycle, the 17% recycled material is reduced. There is value in recycling PET, but the current process requires virgin PET material inputs each cycle.

Recycling of mixed fibres, like poly-cottons, is more difficult. Chemical processing to separate mixed fibres have proven successful in small batches, with pre-consumer waste like manufacturer deadstock. Chemical depolymerization requires heat, washing, and careful sorting, often making the process less “sustainable” than producing virgin cotton or even polyester.

Scaling the process is complicated. To make up the quantity, post-consumer textiles are sourced from mixed recycling collections. These will include metallic dyes, chemical coatings like fireproofing, hidden fasteners, and unlabelled fibre content. Even minor contaminations limits scaling the chemical processing (Marusic (2024), Gusein (2025)).

Alternatively, a mechanical reprocessing can turn some pre-consumer waste fabric, deadstock, into fibre ready for reweaving, at close to 100% re-use, the machine requires clean source material. Post-consumer waste is problematic, due to contamination.

To move towards full circularity in textile recycling, these issues of scale must be addressed. Producing single fibre textiles, like 100% cotton, historically, made recycling easier – the complex make-up of many modern textiles makes recycling equally complex, and often outside consumer capability.

The EU Extended Producer Responsibility (EPR) policy is one solution being trialled requiring textiles to be clearly “labelled” (even at a fibre level) for source and content, enabling full recovery and recycling of materials possible. The policy requires a fee per kilogram of textile manufactured, revenue enabling better recycling systems to internalize end-of-life recovery/recycling costs inside the industry. Systemiq (Hermann et al 2025) calculate that Europe could be recycling ten times more polyester by 2030.

While we wait for EPR policy enabling detailed labelling for recycling, improved chemical detection of fibres in textiles enables better separation during recycling, but are costly and not available to consumers. This lack of information about our clothing structure means we all do a lot of “wishcycling” – putting items in the wrong recycling bins. But keeping textiles out the main waste stream is critical, as piles of unrecyclable textiles grow, consumer demand for improved processes grows too.

Action:

- Use less plastic, generally.

- Buy less non-recyclable materials (like mixed fibre clothing, polystyrene, and bright coloured plastic homeware) planning to “wishcycle” it away (thanks Sam). It never goes away, it either gets incinerated, or goes to landfill.

- Keep recycling carefully! Your clean uncontaminated recyclables in the specified containers at official collection points, even if currently inadequate, can still be useful to organisations developing circular material use systems and get processed, in landfill or incinerated they are lost forever.

- In the UK, check for specific recycling options and locations here: https://www.recyclenow.com/recycling-locator

– In Portugal, here: https://www.ondereciclar.pt/

References

ANDRITZ (2025) Sustainable fashion: ANDRITZ tearing line starts up at Pacific Jeans, Bangladesh, Andritz AG Newsroom. Available at: https://www.andritz.com/newsroom-en/nonwoven-and-textile/2025-05-14-pacific-jeans-group (Accessed: 29 May 2025).

Grant, A. et al. (2022) ‘How circular is PET?’, Zero Waste Europe, 16 February. Available at: https://zerowasteeurope.eu/library/how-circular-is-pet/ (Accessed: 29 May 2025).

Gusein, S. (2025) Does the Circular Story Still Hold Up When You Do the Math? Shivam Gusain, Substack. Available at: https://substack.com/home/post/p-163767835 (Accessed: 29 May 2025).

Hermann, S. et al. (2025) ‘The Textile Recycling Breakthrough: Why policy must lead the scale-up of polyester recycling in Europe’, Systemiq. Available at: https://www.systemiq.earth/reports/the-textile-recycling-breakthrough/ (Accessed: 30 May 2025).

Marusic, K. (2024) Q&A: Director of sustainability at Eastman Chemical Company talks chemical recycling – The Daily Climate, Daily Climate. Available at: https://www.dailyclimate.org/industrial-chemical-recycling-2667644755/particle-1 (Accessed: 29 May 2025).

Plastics and the circular economy (2019) Ellen MacArthur Foundation. Available at: https://www.ellenmacarthurfoundation.org/plastics-and-the-circular-economy-deep-dive (Accessed: 29 May 2025).

Strategy for textiles – European Commission (2022) Official European Commission – TCLF (Textiles, clothing, leather and footwear) industries. Available at: https://single-market-economy.ec.europa.eu/sectors/textiles-ecosystem/strategy-textiles_en (Accessed: 29 May 2025).

‘The climate impact of chemical recycling technologies’ (2020) Quantis, 30 November. Available at: https://quantis.com/reports/the-climate-impact-of-chemical-recycling-technologies/ (Accessed: 29 May 2025).

WRAP – Household Waste Prevention Hub: Re-use – Clothing (2015) WRAP – The Waste and Resources Action Programme. Available at: https://www.wrap.ngo/resources/guide/textiles/clothing (Accessed: 2 June 2025).